Bombardier Learjet Horizontal Stabilizer Actuator

There should never be a time during installation, testing, or adjustment when the potentiometer rods on the actuator are adjusted.

The Duncan Intelligence is a free, technical newsletter for business aircraft owners and operators. Written in-house by Duncan Aviation's technical representatives, each edition includes technical tips and advice on topics and trends in business aviation. It is a free, monthly e-mail subscription for aviation enthusiasts around the world.

Subscribe now to receive the Duncan Intelligence in your inbox.

There should never be a time during installation, testing, or adjustment when the potentiometer rods on the actuator are adjusted.

Sulfation of the plates and damaged terminal studs are common warranty claims that can be prevented or lessened by following simple operational and maintenance procedures.

Troubleshooting an autopilot altitude hold INOP squawk involves a complicated decision tree that includes several steps and scenarios. Here are three questions to get started.

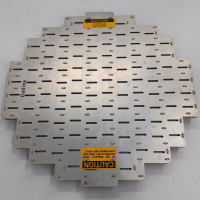

Maintaining the integrity of your weather radar antenna is vital for accurate hazard detection and flight safety. From inspecting physical warpage to ensuring correct system strapping, precise maintenance prevents the false returns and signal smearing that can compromise a pilot’s view of the sky.

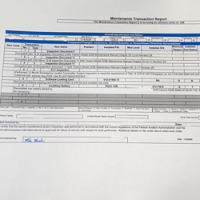

When valuing an aircraft, you either have complete, consecutive, and original logs or you do not. During a pre-purchase evaluation, the logbook plays a major role, and vague or incomplete statements can be troublesome and delay closing.

To avoid contact between the Hawker MLG tire and microswitch cable, frequent visual inspections are necessary.

The FAA mandates that materials on your aircraft undergo burn testing. The airworthiness of your aircraft depends on it.

Not long ago, one of Duncan Aviation's aircraft lost all GPS information and received a number of CAS messages related to these interruptions. What happened?

In this podcast you'll learn why 10% of the Citation Excel/XLS fleet has already upgraded to the Garmin G5000 flight deck.

Making assumptions during aircraft maintenance events can have a major impact on whether a job is done properly or not. Such is the case with sealants.

There are a number of steps you can take before just pulling a unit and sending it in for repair. Any one of them could save you a lot of time and considerable sum of money.

Honeywell authorized Duncan Aviation to perform eddy current corrosion inspections required for two service bulletins

Do not use electric grease guns!

You don’t think much about the temperature sensor in your aircraft’s engine air ducts, until they stop working. Failure can be caused by a number of reasons including cross-threading, broken tabs, or corrosion of the inlet fitting.

Many factors, such as storage conditions or the opening and resealing of the original container, can affect shelf life of de-icers.