Bombardier Learjet Horizontal Stabilizer Actuator

There should never be a time during installation, testing, or adjustment when the potentiometer rods on the actuator are adjusted.

The Duncan Intelligence is a free, technical newsletter for business aircraft owners and operators. Written in-house by Duncan Aviation's technical representatives, each edition includes technical tips and advice on topics and trends in business aviation. It is a free, monthly e-mail subscription for aviation enthusiasts around the world.

Subscribe now to receive the Duncan Intelligence in your inbox.

There should never be a time during installation, testing, or adjustment when the potentiometer rods on the actuator are adjusted.

Sulfation of the plates and damaged terminal studs are common warranty claims that can be prevented or lessened by following simple operational and maintenance procedures.

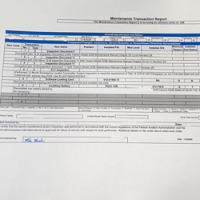

Troubleshooting an autopilot altitude hold INOP squawk involves a complicated decision tree that includes several steps and scenarios. Here are three questions to get started.

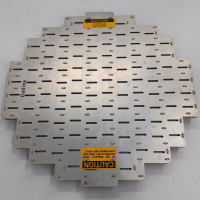

Maintaining the integrity of your weather radar antenna is vital for accurate hazard detection and flight safety. From inspecting physical warpage to ensuring correct system strapping, precise maintenance prevents the false returns and signal smearing that can compromise a pilot’s view of the sky.

When valuing an aircraft, you either have complete, consecutive, and original logs or you do not. During a pre-purchase evaluation, the logbook plays a major role, and vague or incomplete statements can be troublesome and delay closing.

Many BendixKing ART-2100 radar transceivers have not had the software update released in 2018.

The FAA, DOT, Lawmakers, and others in the aviation community have expressed concerns about the potential for the 5G network signals interfering with radar altimeters. Stay informed.

If you are purchasing or selling an aircraft, do not forget to ensure the ELT registration information is updated and correct.

The shortage of available aircraft on the market has created a perfect storm for exploitation and questionable practices by unscrupulous individuals within the sector.

If it’s been more than 14 days and you have flown in any coastal areas around the world, your Citation is overdue for a shower.

If you are experiencing tuning and/or garbled transmitter problems with your KHF-950 system, you may have some outstanding Service Bulletins that should be installed.

Having the right information about the circumstances surrounding a squawk can save your tech rep many hours of troubleshooting time and yourself a considerable amount of money.

There are many articles and documents regarding these concerns. We encourage you to stay informed and provide links to relevant documents.