Bombardier Learjet Horizontal Stabilizer Actuator

There should never be a time during installation, testing, or adjustment when the potentiometer rods on the actuator are adjusted.

The Duncan Intelligence is a free, technical newsletter for business aircraft owners and operators. Written in-house by Duncan Aviation's technical representatives, each edition includes technical tips and advice on topics and trends in business aviation. It is a free, monthly e-mail subscription for aviation enthusiasts around the world.

Subscribe now to receive the Duncan Intelligence in your inbox.

There should never be a time during installation, testing, or adjustment when the potentiometer rods on the actuator are adjusted.

Sulfation of the plates and damaged terminal studs are common warranty claims that can be prevented or lessened by following simple operational and maintenance procedures.

Troubleshooting an autopilot altitude hold INOP squawk involves a complicated decision tree that includes several steps and scenarios. Here are three questions to get started.

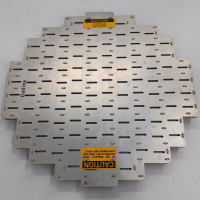

Maintaining the integrity of your weather radar antenna is vital for accurate hazard detection and flight safety. From inspecting physical warpage to ensuring correct system strapping, precise maintenance prevents the false returns and signal smearing that can compromise a pilot’s view of the sky.

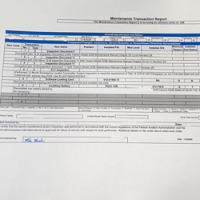

When valuing an aircraft, you either have complete, consecutive, and original logs or you do not. During a pre-purchase evaluation, the logbook plays a major role, and vague or incomplete statements can be troublesome and delay closing.

This area becomes susceptible to corrosion when there is a lack of lubrication on the piston rod felt wiper.

Duncan Aviation is offering bench software upgrades for Service Bulletin AS907-76-9031 that will save operators time and money.

The Hawker aileron trim jack needs to be exercised on a regular basis to be kept properly lubricated and operational.

A solid seal around the radome will help prevent corrosion of the avionics units inside.

Six pitfalls of a non-exclusive aircraft sales relationship.

Duncan Aviation offers a more cost-effective option than the high replacement cost.

Learn more about the benefits, advantages, and pricing of these avionics protection coverage programs.

Ahead of a scheduled flight, pilots and DOMs should test their datalink systems to ensure they are able to connect and request and receive valuable flight information.

It's time to upgrade to flash memory technology.

Watch the video and learn how to properly configure the interfaces of your aircraft's Avidyne EX500/600 MFD.