Bombardier Learjet Horizontal Stabilizer Actuator

There should never be a time during installation, testing, or adjustment when the potentiometer rods on the actuator are adjusted.

The Duncan Intelligence is a free, technical newsletter for business aircraft owners and operators. Written in-house by Duncan Aviation's technical representatives, each edition includes technical tips and advice on topics and trends in business aviation. It is a free, monthly e-mail subscription for aviation enthusiasts around the world.

Subscribe now to receive the Duncan Intelligence in your inbox.

There should never be a time during installation, testing, or adjustment when the potentiometer rods on the actuator are adjusted.

Sulfation of the plates and damaged terminal studs are common warranty claims that can be prevented or lessened by following simple operational and maintenance procedures.

Troubleshooting an autopilot altitude hold INOP squawk involves a complicated decision tree that includes several steps and scenarios. Here are three questions to get started.

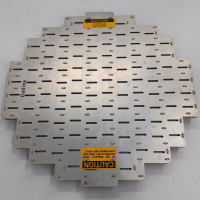

Maintaining the integrity of your weather radar antenna is vital for accurate hazard detection and flight safety. From inspecting physical warpage to ensuring correct system strapping, precise maintenance prevents the false returns and signal smearing that can compromise a pilot’s view of the sky.

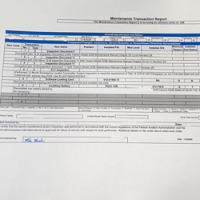

When valuing an aircraft, you either have complete, consecutive, and original logs or you do not. During a pre-purchase evaluation, the logbook plays a major role, and vague or incomplete statements can be troublesome and delay closing.

Selecting the right business jet is a high-stakes investment, but the sheer volume of data can make narrowing your search feel overwhelming. Duncan Aviation has simplified this process with an updated Model/Market Summary that compares everything from hourly operating costs to full-seat range across the latest airframes. Check out how this tool can streamline your next acquisition and help you identify the perfect model for your mission.

A fresh coat of paint is more than just a cosmetic upgrade—it’s a regulatory event that varies significantly by jurisdiction. While the FAA views painting as routine maintenance, authorities like EASA classify it as a design change requiring formal approval. Learn how understanding these regional nuances can help you avoid costly administrative delays and keep your aircraft compliant across international borders.

As business aviation fleets modernize, many aircraft are still carrying the literal weight of the past. Removing obsolete avionics and legacy antennas can reduce maintenance burdens, improve performance, and boost resale value. This article explores why streamlining your aircraft’s configuration is a strategic investment in long-term operational efficiency.

Customers often assume failures can’t happen when they aren’t flying but talk to any of Duncan Aviation’s Satellite Shops, and we’ll confirm it’s a very common occurrence.

What can ground an aircraft faster than a failed component? Documentation. When you think about what keeps your aircraft airworthy, you usually think of tangible systems such as engines, avionics, landing gear, and flight controls. Rarely does paperwork top the list. It should.

As 2025 comes to an end, ACS Rep Rene Cardona reflects on what shaped this year’s preowned business jet market. The fourth quarter is always busy, but this year brought a unique level of intensity, driven by economic uncertainty early on and a surge of confident buyers later. Here’s his perspective on what we experienced in 2025—and what to expect as we head into 2026.

Don't get grounded by confusing nose wheel vibrations! A true nose gear shimmy—that rapid, side-to-side oscillation—is a serious issue often linked to play in the torque links, requiring immediate mechanical attention. In contrast, a simple vertical shudder felt during taxi or initial climb is often just an easily corrected wheel imbalance. This quick guide details the key differences and the essential steps to accurately troubleshoot the condition, starting with a simple inspection of the nose gear scissors.

Is your aircraft compliant? Missing small inspections tied to STCs or life-limited parts can lead to costly downtime and mandatory replacements. Learn why detailed records research is essential.

Don't Let Your Spare Aircraft Batteries Go Flat! Keeping a stock of essential aircraft batteries is crucial for operational readiness, but did you know that improper storage can drastically cut their lifespan and capacity? While temperature affects performance in the air, the storage environment is key to minimizing self-discharge and maintenance needs. Discover how optimizing storage temperature—from the effects of higher heat to the benefits of cold storage—can save you money, extend battery life, and ensure your spares are ready to deliver maximum performance when you need them most.

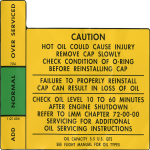

Honeywell has issued two Category II Reliability Service Bulletins, TFE731-79-3070 R1 and TFE731-79-5120, for the installation of new instruction plate decals on oil tanks to help prevent oil over-servicing.