Duncan Aviation has touched thousands of business aircraft interiors over the years, and we consistently look for ways to make work more efficient while maintaining the high-quality products for which we are known.

Upholstery methods in particular have seen significant evolution, integrating automated technologies and the latest automated software advancements. The result is a transformation of our upholstery processes that increases client options and allows for some truly amazing custom touches.

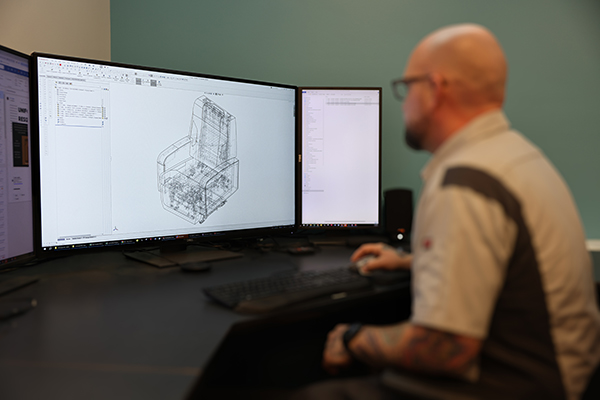

Upholstery automation includes machinery for the precision cutting of seat covers and foam, computerized sewing machines for stitching and quilting, and the utilization of automated design software to create seat models, optimize foam for comfort, and generate dress cover patterns tailored to customer specifications.

“The journey of automation has been like embarking on a wild roller coaster ride that’s filled with exciting highs, challenging lows, and unexpected twists and turns,” says Upholstery Automation Team Leader Nick Graham. “It involves incorporating automated technologies and processes into the design, creation, and production of upholstering aircraft cabin seating.”

The shift towards automation in our Upholstery Shop brings several tangible benefits, such as increased consistency and repeatable design capabilities. This not only enhances the aesthetic appeal of the final products, but caters to the diverse preferences of our customers. It has sparked a transformative evolution, with increased utilization of advanced technologies to meet the demands of modern manufacturing and design.

Our upholstery automation journey began with the initial purchase of a CNC leather cutting machine, purchased over 20 years ago, marking the introduction of automated processes. Later, this investment extended to the purchase of automated design software for advanced pattern making and collecting reusable aircraft seat data, further enhancing consistency.

The additions of patterning software, along with updated CNC machines with the newest technology, signify a continued commitment to automation, demonstrating a progression towards cutting-edge software and tools that contribute to improved productivity and streamlined operations. In essence, this journey of automation reflects Duncan Aviation’s dedication to staying at the forefront of automated technological innovation in the realm of upholstery and providing clients with the absolute highest quality products in the aviation industry.

Transitioning to automated seat processes, particularly with seat covers, has shown enhanced consistency between seats. While the traditional processes of designing and refurbishing cabin seats are still a valuable part of the quality services being provided, the automated seat design and fabrication process has significantly increased our capabilities. The wealth of automated seat data accumulated over the past five years enables us to repeatedly utilize this information, enhancing our ability to provide optimized support internally and to our customers.

All three Duncan Aviation upholstery shops in Lincoln, Nebraska, Battle Creek, Michigan,

and Provo, Utah, have seen significant transformations and improvements over the years. The most recent transformation is our expansion of the Upholstery Shop in Lincoln. It is designed to enhance the efficiency of our seat reupholstering processes. This includes a new humidor room and specialized leather racks for storage, adjustable tables facilitating optimal disassembly and reassembly of aircraft cabin seating, mobile seat storage, a dedicated area for leather and seat inspections, a new paint booth, and upgraded CNC machines.

Additionally, our upholstery processes have taken a significant step forward with the introduction of a 5-Axis CNC machine. This machine has transformed processes by facilitating intricate and precise cutting and shaping of cabin seat foam. The incorporation of the 5-Axis machine has led to heightened consistency in both cabin seat foam and dress covers. The machine’s versatility enables us to craft complex and customized designs with accuracy, ensuring a higher standard of quality in our upholstered products.

These improvements aid in creating high-quality seat products that maintain their appearance. These developments stand as clear indicators of the Upholstery Shop’s firm dedication to fostering innovation.

When automating a cabin seat, our design software is utilized to automate the foam and dress covers based on a specific seat frame. Initially, the existing cabin seat is disassembled to the frame, and precise measurements are recorded. 3D models of the seat frame and foam are then created based on this documentation and seat drawings. These seat foam models are transferred to the software, where seat cover patterns are created along with sewing instructions. The automated cover patterns are sent via file to the CNC machine, which cuts them out from the specified material designated for the project. The foam models are sent to be cut using the 5-axis machine.

Looking ahead, the Upholstery team is poised to continue its journey of innovation. This includes further integration of advanced technologies and continuously refining processes to keep pace with design trends and customer expectations. The commitment is to set new benchmarks for excellence in the aviation industry regarding upholstery.

In the world of upholstery, Duncan Aviation stands out through a combination of factors that define our unique value proposition. This dedication to innovation enhances precision, efficiency, and customization in our upholstery processes, providing our customers with a superior level of service. It is the combination of technological innovation, skilled artisanship, teamwork, and a customer-focused approach that distinguishes Duncan Aviation as a leader in the field of upholstery in the aviation industry.