Bombardier Learjet recently released the following Alert SBs (Service Bulletins) regarding Nacelle Heat Anti-Ice Tube Cracking:

As announced in the Advisory Wire AW30-016 on April 27, 2016, there was a “Call in Session” with Bombardier Learjet that answered many questions surrounding this issue. If you were not able to participate, I hope the following will help you understand the situation better. The Nacelle Heat Anti-Ice Tube Cracking issue affects 662 aircraft.

The released SBs are only for inspecting the inlets for the cracked Nacelle heat tubes. The SBs clearly illustrate there are only two areas of the tube that are to be inspected: the forward and aft end of the nacelle heat tube in the inlet.

Some items discussed during the call are as follows:

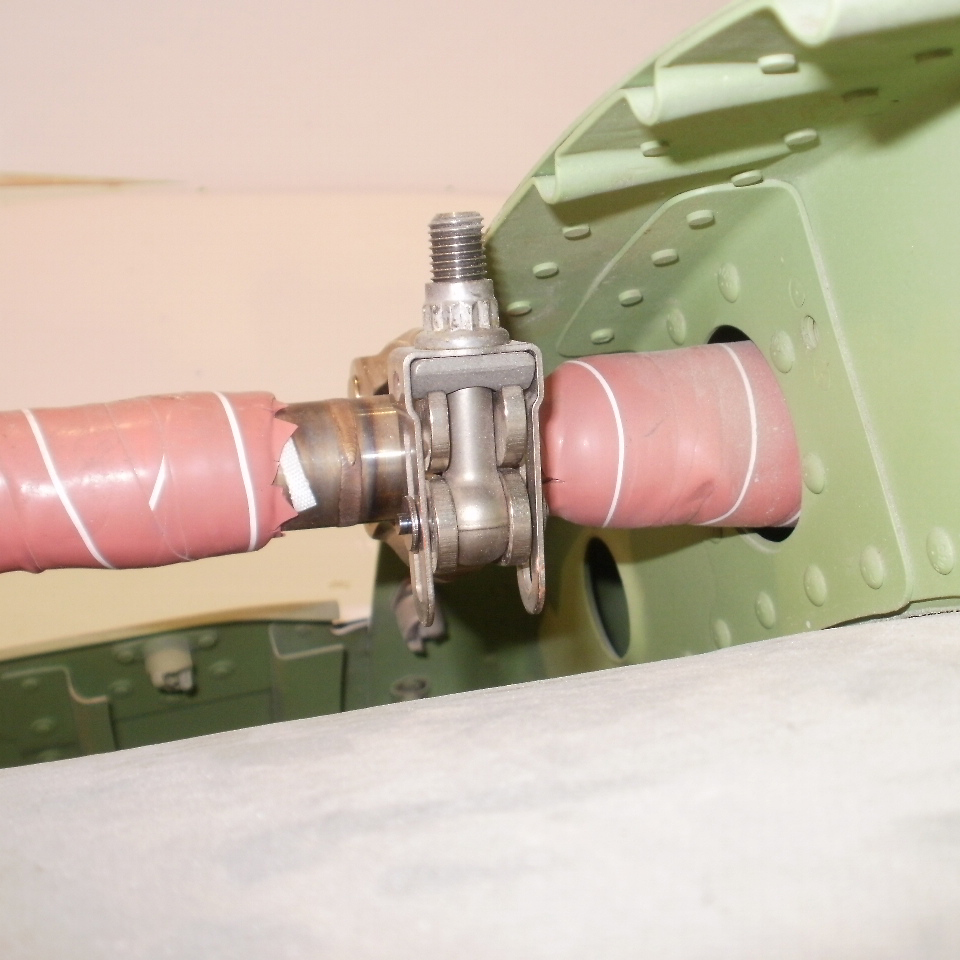

The tube being inspected is wrapped in insulation and then covered in a pink, rubber-like tape, commonly called F4 tape. The tape, where it continues past the end of the insulation and is directly on the tube, may look discolored or even burnt. This could be a normal reaction due to the heat from the tube. It may not be an indication of a crack; however, it does not rule it out either.

A Borescope Is Required

Because the forward area of the nacelle heat tube being inspected is not so readily visible, a borescope is required for inspection. The SB calls out to gently work the aft end while inspecting the forward end, internal and external, with the borescope. If the end that you are moving with your hand feels loose, that is probably a cracked tube.

Another inspection method that should be used is to apply some leak detect (soapy water) around the area in question and apply a small amount of air pressure, 5-15 PSI, and observe the area while gently working the tube by hand back and forth.

If you find damage, please complete the entire inspection before contacting Bombardier Learjet with your findings.

Collateral Damage

Another issue to be aware of is the collateral damage caused if the tube is cracked. Since there is no external evidence or indication in the cockpit, you may not know that it is cracked or for how long.

If cracked, the tube can be repaired by being TIG welded with Argon shielding gas. Duncan Aviation has this capability and is able to repair what is accessible. Please be advised, the inlets on these model aircraft are not assembled the same as earlier model Learjet aircraft. Please contact us for more information and to discuss repair options if there is damage to the inlets. We can also assist with advice regarding rental inlets.

Turntimes Discussed

|

Duct Bond (composite barrel) |

8-10 days, if damaged & needs replaced |

|

Cracked bulkhead |

19 days |

These turntimes are NOT guaranteed and will depend on the shop loading at Bombardier Learjet.

Revision of Inspection Program

Bombardier Learjet announced there is a revision to the inspection program coming in June of 2016 that will add this inspection task on a 250-hour interval to Chapters 4, 5 & EMP. The Chapter 4 Temp Revisions have been released for the 40 (TR 4-28) & 45 (TR 4-40) models. There will be another SB issued to terminate this inspection requirement, once a permanent solution is defined.

*Trademarks of Bombardier Inc. or its subsidiaries.

February 2026

February 2026

February 2026

February 2026

February 2026