Unlike engines and other mechanical systems – where maintenance is often scheduled based on flight hours – de-ice boots can be subject to wear or damage whether an aircraft is in the air, on the tarmac, or even in a hangar. This means the boots used in Collins Aerospace Goodrich pneumatic de-icing systems require ongoing attention and care. A critical factor in maintaining the de-icing system is a regular schedule of inspection, repair, and/or replacement.

Inspection

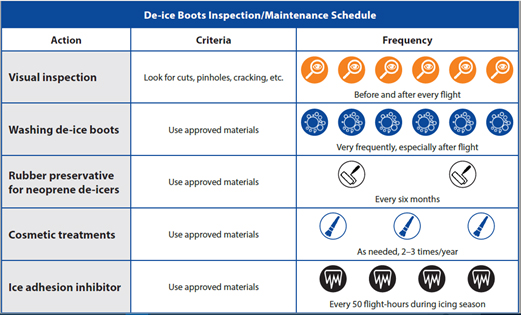

De-ice boot inspections should be performed before and after every flight. After landing, wash the boots with mild soap and warm water to remove insects and other debris before it dries. After boots are cleaned and dried, perform a visual inspection for damage of any kind. It is relatively easy to detect even minor surface imperfections by looking along the length of the boot’s leading edge under a good reflecting light source.

Preventive Maintenance

While physical damage to pneumatic de-ice boots can happen at any time, most age-related deterioration affecting longevity or reducing de-icing performance can be forestalled by proper preventive maintenance. In addition to frequent cleaning and inspection, regular preventive maintenance consists largely of using manufacturer-approved care products. These treatments protect the neoprene from ozone damage, reduce cosmetic UV fading, and often enhance the performance of the de-icer.

Conclusion

Frequent inspections and regular maintenance is critical to the proper performance of pneumatic de-ice boots and their contribution to overall flight safety. By identifying problems early and effecting immediate repairs or boot replacement, the airworthiness of the aircraft can be assured.

For further information on installing, maintaining, and cleaning the de-icers, contact:

Arlo Paton, Avionics Tech

Duncan Aviation Seattle (BFI) Avionics Satellite

+1 206.764.3962, Arlo.Paton@DuncanAviation.com

This article was written by Collins Aerospace Goodrich for the Duncan Intelligence.