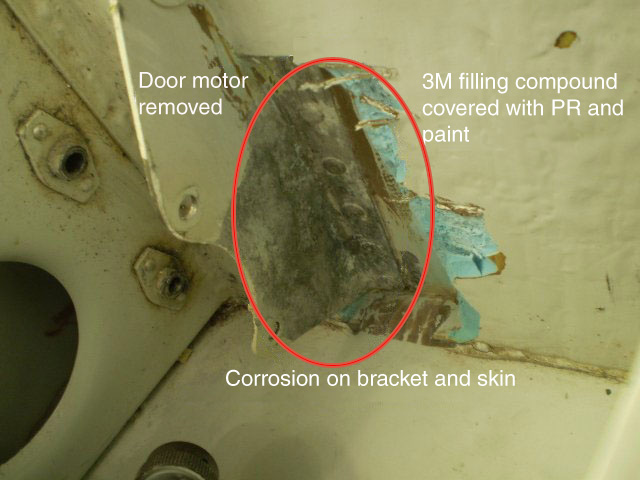

A crucial area for inspection on your Falcon 900 involves the potential for water ingress and subsequent corrosion near the baggage door motor. The design in this area features a slope under the Falcon 900 baggage door motor, intended to direct water away from critical components. This slope is formed using a blue 3M filling compound, sealed with a protective layer of sealant and paint.

The effectiveness of this protection hinges on the integrity of the sealant. If the sealant is compromised, water can penetrate and become trapped within the lightweight filler material. This trapped moisture can then initiate corrosion. Also note that the opening for the door cable in this panel does not provide a complete seal, increasing the vulnerability to water intrusion.

Recommend carefully inspecting the door motor bracket to proactively address this potential issue.

Should any corrosion be found:

Regular inspection of this area can help prevent significant corrosion-related issues, and application of Approved CIC (corrosion inhibiting compounds) in this area will help as well.

If you have any questions or require further clarification on this or any other Falcon technical matter, please contact me.

December 2025

December 2025

December 2025

November 2025

November 2025